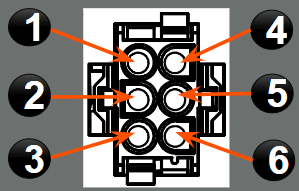

6 Pin Out From AC to Control Box

- Terminal 1 BLUE Compressor

- Terminal 2 BLACK High Fan

- Terminal 3 YELLOW Medium Fan

(or Heat Pump Rev Valve CCC/Analog) - Terminal 4 RED Low Fan

- Terminal 5 WHITE Neutral

- Terminal 6 GREEN/YELLOW Ground

(Ground is sometimes GREY)

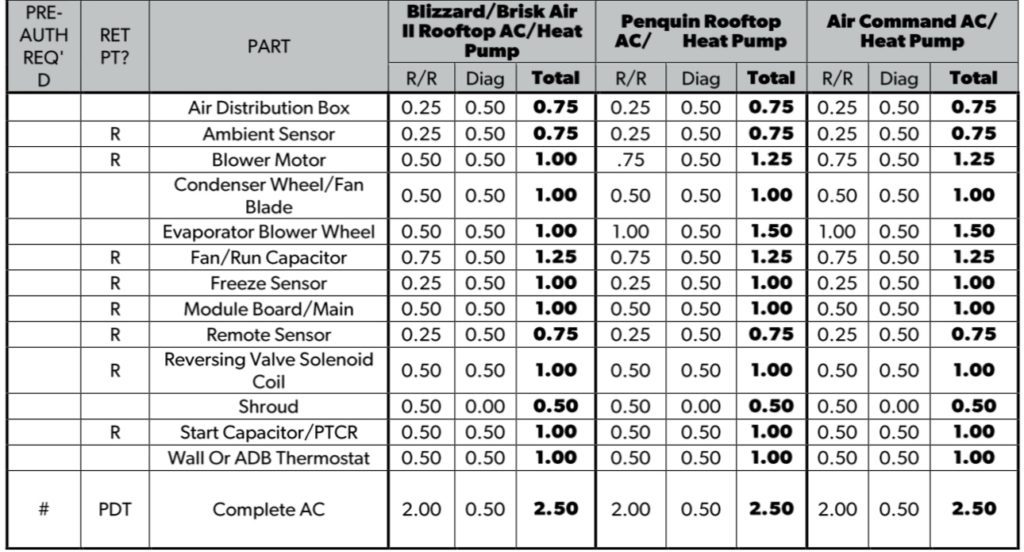

Manufacturer Flat Rate Schedule

The diag time is sometimes stackable on the manufacturer warranty as a separate code paid by Dometic